EFFICENT KITTING & PACKING

- Sometimes workers need to interrupt their functions to physically check paper instructions lists, which will cause major time losses in manufacturing production lines.

- When setting up kits or packs, the workers might occasionally mix-up parts and pieces, therefore making costly errors.

- Production lines might be consistently affected by the same errors, without knowing how to fix them. Do you wish you could prove without doubt that all manufactured products were sent error-free?

- KIT-AR’s Kitting & Packing product, can help you solve all these pain points that are affecting your company!

SHOPFLOOR PROCEDURES FULLY DIGITAL

Easily solve workers doubts and reduce errors, when packing up parts or creating kits. With on demand instructions, your shopfloor procedures can now be fully digital!

- Go back and trace where errors occurred in production lines

- Prove without a doubt that all manufactured products were sent error-free

- Quickly produce evidence to guarantee total quality assurance

- Identify continuous improvement opportunities on the shopfloor

CONTINUOUS IMPROVEMENT IN MANUFACTURING

Guarantee total quality assurance on your manufacturing shopfloor, with KIT-AR’s Kitting & Packing product:

- Establish and digitalize standard process

- Photo evidence capture

- Ensure quality traceability

- Ability to resume previously pauses jobs

- Monitor process data

- Register error types and bottlenecks with insight and live reporting

- Record and flag error(s) (from pre-defined classification list) at the point of occurrence

- Record partially completed host stillages as ‘On-Hold’ requiring rework

OUR KITTING & PACKING SUCCESS

Honorable mention in Logistics

The Kitting & Packing product won an honorable mention in the category of logistics, delivery and returns, at the CTT Ecommerce Awards, 2022 edition

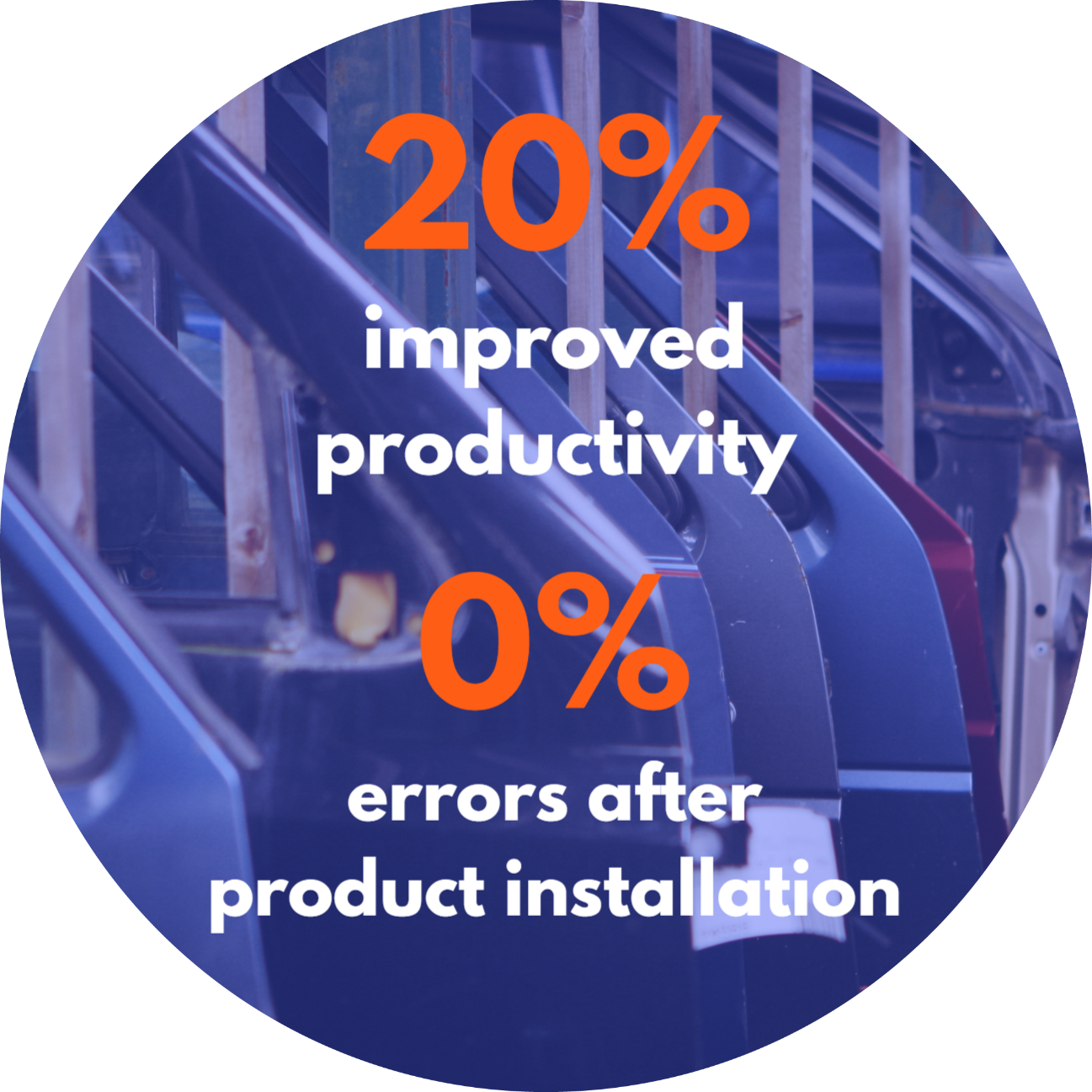

Improving in Automotive: Case Study

The first automotive customer that used the Kitting & Packing product identified a 20% improvement in productivity, a number that had never been reached before in the company. 0% errors were as well noted after the product installation.